Commodity: Automatic Soap Production Plant

HS Code: 84798200

Production Capacity: Customizable lines with outputs ranging from 100 to 1000 kg per hour, adaptable to diverse production scales.

Applications: Efficiently manufactures both bar soap and bathing soap, catering to consumer and commercial hygiene product needs.

Fully automatic soap making machine line

Fully automatic soap making machine

1.Enhanced Productivity: Robust capacity of 100–300 kg/h ensures high-output production, optimizing throughput for scalable operations.

2.Consistent Quality Assurance: Produces soap with superior aesthetics, firmness, and texture, meeting stringent quality standards for market appeal.

3.Labor Efficiency: Streamlined operation requires only 6–8 personnel per line, reducing manpower dependency and associated costs.

4.Cost Optimization: Minimizes material waste, energy consumption, and labor input, delivering long-term savings without compromising performance.

5.Core Benefit: Accelerate market entry with efficient, high-quality output, gaining a competitive edge in fast-paced industries.

Equipped with a renowned domestic hard - gear reducer from a leading brand, ensuring durable and long - lasting operation!

Batch capacity: 50 kg per batch

Mixing time: 5 minutes

Designed to ensure uniform blending of soap particles and additives, creating a compact soap structure with enhanced density and superior quality.

Technical specifications: Roll diameter Φ150 mm, roll face length 300 mm.

DUPLEX PLODDER MACHINE

SOAP CUTTING MACHINE

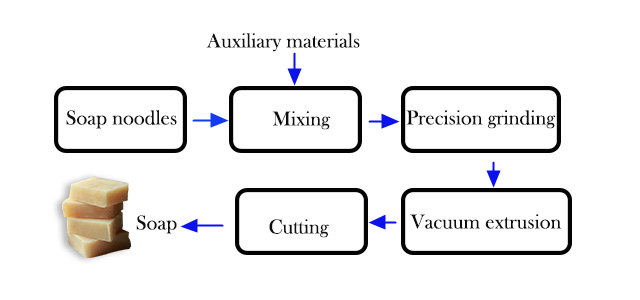

The fully automatic soap making machine embodies technological innovation, streamlining production from saponification to packaging for efficiency, consistent quality, and minimal waste. Its customizable design adapts to diverse soap types, while intuitive controls and robust construction ensure reliability for large-scale output. Backed by expert support, it reduces costs, enhances productivity, and delivers market-ready products, making it an essential solution for manufacturers seeking competitive edge and growth.